Reservoir Number Nine in San Clemente, CA faced a tight spot when a 12-inch corroded steel pipe needed to be replaced. The pipe was located in a large potable water storage tank – about the size of a football field. Water is pumped through a pump station into the vault through the pipe and dispersed throughout different areas in the tank.

From the start of the installation, there was one problem that had to be addressed. The only access to the reservoir storage tank was through a 36-inch square access way at the top. The small access point reached 22 feet from the top down to the floor of the tank. The contractor on the project, NEWest Construction, needed a way to fuse the replacement pipe once it was inside the storage tank.

The project, which began in February 2010, was time-sensitive so the pipe had to be fused quickly. Clem Miner, the NEWest Construction superintendent on the project, knew it would not be easy to get a fusion unit into the reservoir through the small entrance.

The ISCO Solution

ISCO Industries, a total piping solutions provider, was there to offer a solution. Several fusion options were considered. The first option was electrofusion, but this did not meet budget or time criteria. Electrofusion can be labor intensive and with 17 joints requiring fusion, this was not a timely enough option. The second option was to take a McElroy No. 412 unit off of its base and use extension hoses to reach down through the access point. However, reaching extension hoses down 22 feet and potentially 100 feet across was not a viable option. In addition, it would still be a tight fit through the access way.

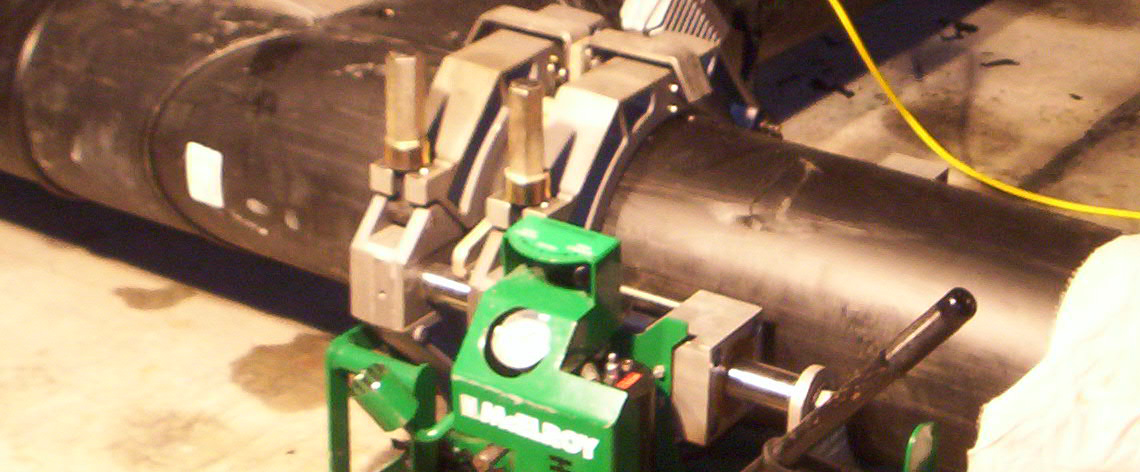

After much thought and discussion, ISCO representative Darin Predmore offered another solution, the McElroy DynaMc™ 412 hand pump fusion unit. Both the 2-Jaw and 4-Jaw units had a maximum width of only 32 inches, which made the unit an option to get into and through the 36-inch reservoir access way. The hand pump does not require hydraulics and is lightweight, which made fusion easy and fast.

ISCO also supplied 280 feet of 12-inch DR 17 high-density polyethylene (HDPE) pipe, as well as fittings and a fabricated outlet structure that ISCO made for any overflow. After a test joint was made using the fusion unit and a bend back test was successfully completed, the contractor was on their way to completing the fusion job on time. The bend back test was so successful that daily tests were not required by the inspector, saving the contractor money.

This was the first time the DynaMc was used in Southern California and was a new addition to the ISCO Southern California rental fleet. It proved to be the best solution to the customer’s problem.

“As you know, this project required the installation of 255 feet of 12-inch DR17 HDPE Pipe inside a 3.5 million potable water tank, where access to the tank was limited thru a small 36-inch square hatch,” said Miner. “The McElroy DynaMc 412 HP was the perfect fit for this project. Because of its compact size, it solved the problem of having limited access thru the 36-inch square hatch and gave me the maneuverability needed inside the tank to complete the complex fusion tasks required. The ease of use and the double action hand pump made critical opening and closing of the fusion process a cinch.”

The project was completed within budget and on-time, despite the small entrance to the reservoir.

SUBSCRIBE TO ISCO UPDATES

ISCO Updates

[gravityform id="21" title="true"]