Building a Legacy

For the first time in more than 40 years, a new greenfield potash mine is now open in Saskatchewan. K+S Potash Canada (KSPC) recently opened the Bethune mine and production facility, formerly called the Legacy Project) located in the RM of Dufferin #190, near the communities of Bethune and Findlater.

The $4.1 billion mine has created new job opportunities and new business opportunities for local companies supplying materials and labor to this development. It has impacted Saskatchewan’s economy by improving employment, tax revenues, utilities, and local partnerships.

KSPC is working with Design and Project Management partner Amec Foster Wheeler (Amec FW). The mine is projected to reach the two-milliontonnes-mark of production capacity by the end of 2017.

HDPE Pipe for Slurry, Brine, Centrate, Salt and Process Lines

When it came to choosing material for slurry lines, brine lines, centrate, salt slurry, and process water, AMEC FW wanted a high-quality, wear-resistant product that could withstand the abrasive applications. They chose ISCO to provide approximately four million pounds of high-density polyethylene (HDPE) pipe. Materials included bare and insulated HDPE. The sizes ranged from three-inch DR7 to 36-inch DR9. In addition to the pipe, ISCO also provided a ton of custom fittings. Included in the project were arc bends, mitered elbows, anchors, flanges, tees, and saddles. ISCO has the ability to fabricate fittings to suit the customer’s need no matter the complexity of the job.

Jobsite Support

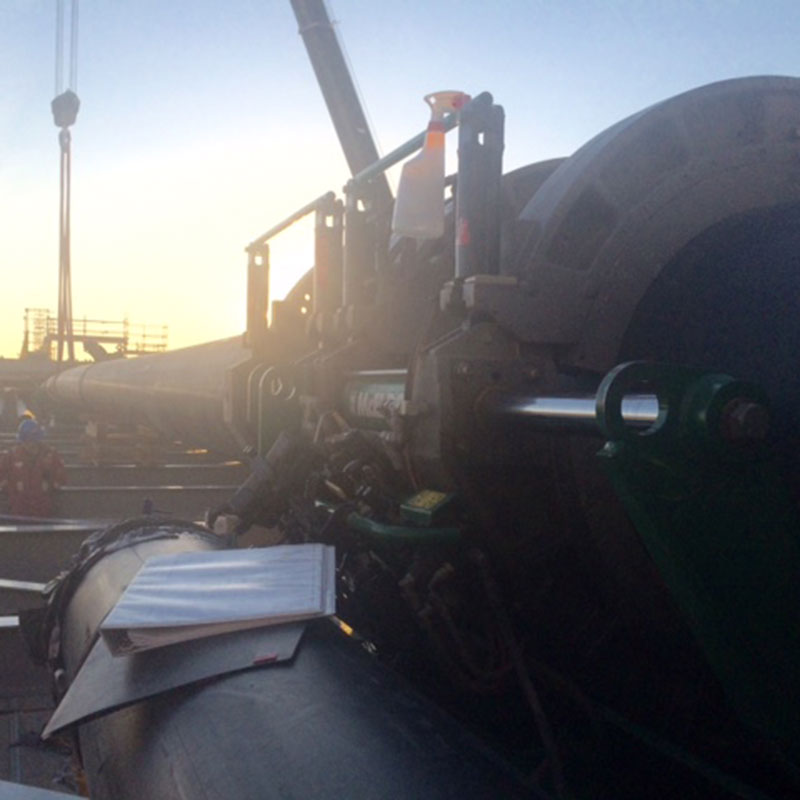

The contractor on the job was Site Energy Services, Inc. They worked with ISCO on securing fusion to join the pipeline and add the fittings. ISCO fusion technician Simon Crowe served on site as a both a tech and a supervisor of sorts, to ensure that all the fusions were completed to the highest standard. For the six months of fusion work, five McElroy T-900’s, two MegaMc Polyhorses to hold and feed the pipe, three regular polyhorses, five McElroy Pit Bull 28 machines, as well as numerous electrofusion processors and DataLoggers.

ISCO was able to provide not only the material to complete the basic pipeline, but the customized fittings to make sure it met design requirements. With the fusion equipment and expertise provided by ISCO, KSPC will have piping systems to last for decades and keep up with the life of the mine.

SUBSCRIBE TO ISCO UPDATES

ISCO Updates

[gravityform id="21" title="true"]