Lithium-ion battery powered electrofusion machine designed to work all day, every day

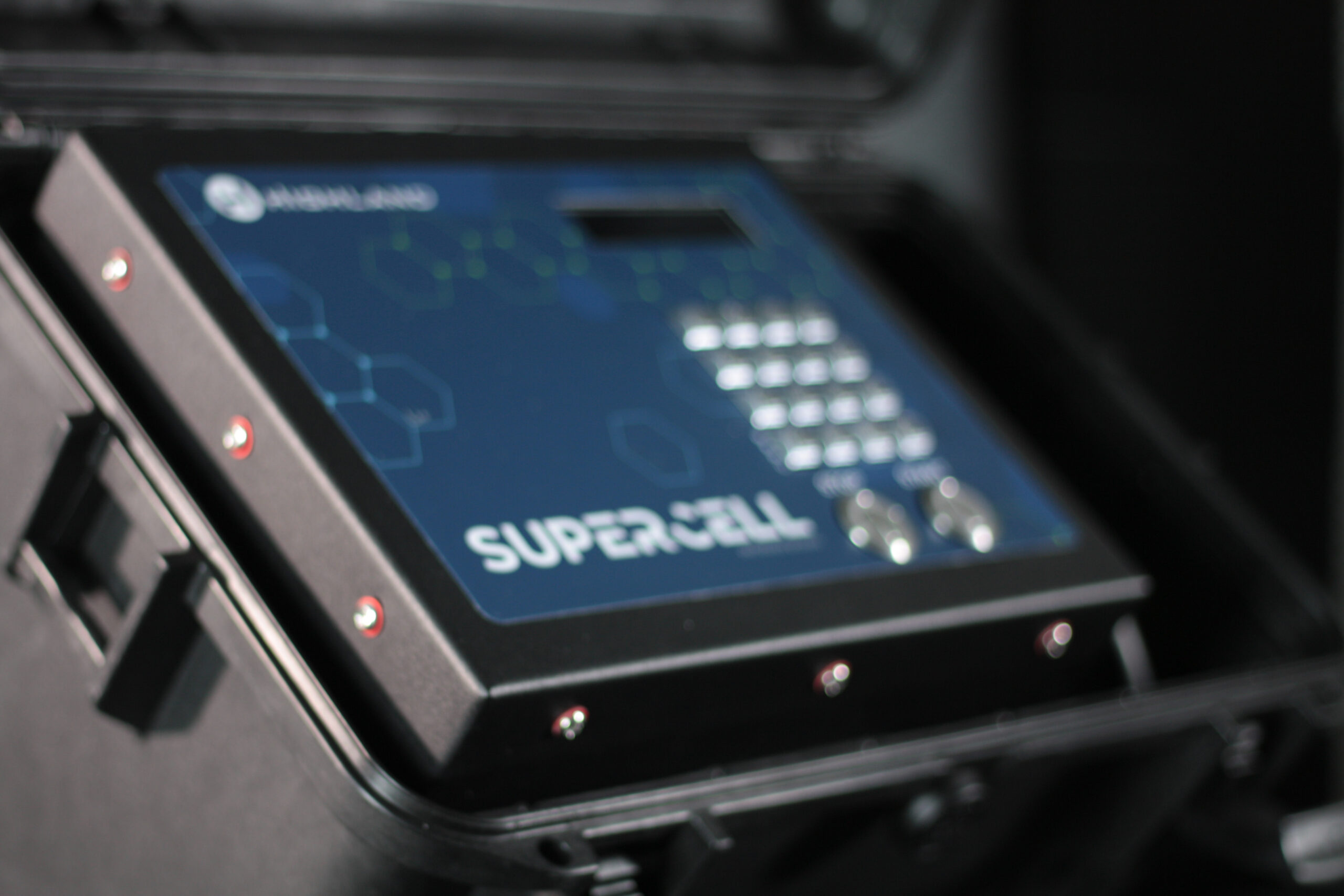

Introducing Supercell, a generational leap in electrofusion technology.

The Supercell is a state-of-the-art device used for the joining of polyethylene (PE) pipes and fittings by electrofusion.

The high-powered electrofusion machine delivers superior performance and results, making it a popular choice for demanding industrial, water and gas distribution, irrigation, mining, landfill, and commercial fusion applications.

Industry experience

ISCO has years of experience and expertise installing HDPE pipe for a wide range of applications including municipal, industrial, energy, geothermal, landfill, gas distribution, and more.

Product advantages

HDPE pipe is strong, durable, flexible, lightweight, and has a zero leak rate. It is environmentally sustainable, corrosion- and chemical-resistant, has a long design life, and ideal for trenchless installation methods.

Training and service

At ISCO, our value goes beyond the products we sell. We provide onsite and custom electrofusion training, fabrication, and project management services that form a complete solution for your projects.

The Supercell Advantage

Leak-free solution

Easy installation

60 Minute recharge time

Lightweight, completely silent operation

98% Reduction in carbon emissions

Lithium-ion battery powered

SUPERCELL RESOURCES

Supercell Performance and Service FAQs

On a full charge, an experienced operator can expect approximately two weeks worth of work from one battery charge.

| Fitting Size and Type | # of Fusions on Full Charge* |

|---|---|

| 1/2" coupling | 200 + |

| 1" coupling | 200 |

| 2" coupling 2" tap tee |

40 68 |

| 4" coupling 4" tap tee |

8 28 |

| 6" coupling 6" tap tee |

4 28 |

| 8" coupling 8" tap tee |

3 26 |

| 12" coupling 12" tap tee |

1 12 |

The Supercell weighs 31 lbs and offers more than 100 percent weight savings versus the average generator-powered processor, along with the generator and supporting equipment, which can weigh up to 250 lbs.

The Supercell is equipped with more processing power than your average processor. This allows the unit to measure the available charge and calculate the energy needed to fuse. Supercell will not allow you to start a fusion it can’t finish.

Utilizing fast charge technology, Supercell can be charged from flat to full in about 60 minutes using its wall outlet charger. A 12V auxiliary vehicle charger also comes standard with Supercell. If you can’t wait an hour, the energy needed to fuse a 1.25” service connection can be charged in just ten minutes.

In most cases, no. The Supercell has been designed and tested to operate in temperatures between -4°F and 110°F. Supercell can be charged in temperatures ranging from 32°F and 120°F.

Once every two years.

The battery pack powering Supercell has been designed to last for at least 500 full charge cycles. This design along with advanced battery management technology means that even the heaviest of users can expect at least five years out of the battery pack.

On average, a traditional generator-powered processor produces around 344kg of CO² in a year. Charging the Supercell with electricity to do the same amount of work will produce around 8kg of CO². If carbon-neutral energy is used to charge Supercell, it becomes net-zero with a 100% reduction in emissions.

Silent. 0db. With no running generator, remove potentially harmful unwanted or disturbing sounds from you job site.

With no generator, Supercell greatly reduces slip, trip, and fall hazards. With its smaller form factor and lighter weight, risks for lifting and handling injuries are also reduced.

Supercell is equipped with the latest hardware that allows it to easily communicate with mobile phones, GPS satellites, and Bluetooth®-enabled devices.

Supercell Product Brochure

The world's first li+battery powered electrofusion processor designed to be used all day, every with a batter pack. Average users get two weeks of work out of every battery pack before needing to recharge.

Supercell Operations Manual

Refer to the Supercell Operations Manual for for descriptions and procedures, instructions and guidance, as well as for use by operational personnel in the execution of their duties.

Data Plus - Fusion Record Viewing Software

Designed for electrofusion in the field, Data Plus records and monitors fusion data.

Download Data Plus software to collect and store data related to your fusions, including fusion parameters, welding time and cooling time. This data can then be used for quality control purposes and to ensure that your fusions meet industry standards and regulations.

Specifications

Operating Temperature

-4°F to 113°F

Data log memory:

>10,000 fusions

Charging Temperature:

32°F to 113°F

Protection Level:

IP54

Fusion Voltage:

8 to 48 V ac (39.5 V)

Weight:

31 lbs

Fusion Current:

1 to 65 A (true rms)

Dimensions:

17” x12” x 12”

Fusion Power:

8 VA to 2600 VA

Warranty Period:

2 years

Fusion Time:

1 to 3000 seconds

17” x12” x 12”

2 years

Charger Supply Protection:

Class 1 – Grounded

Standard GPS Equipped

HAVE A QUESTION OR PROJECT TO DISCUSS? GET IN TOUCH!

[gravityform id="11" title="true"]