McElroy Optimized Cooling

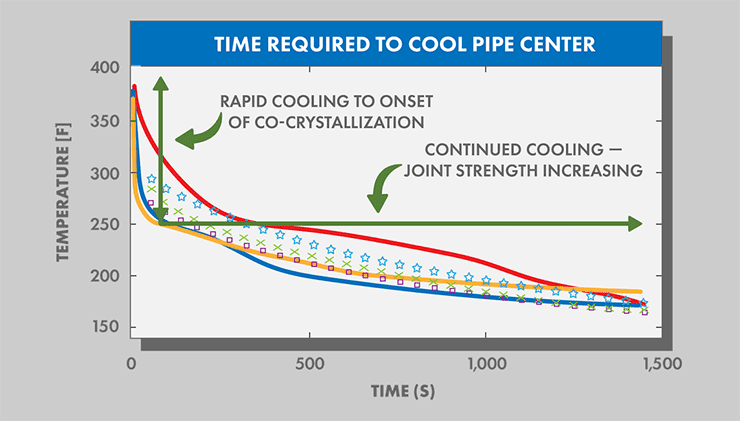

Cooling is the longest step in the fusion process. McElroy's Optimized Cooling™ is a proprietary, patent-pending algorithm designed to decrease cooling time within ASTM standards for increased jobsite productivity.

Optimized Cooling™ technology uses McElroy’s advanced DataLogger® software to calculate, in real time, the most appropriate cool times based on material properties, environmental conditions and other factors so you can move on to the next joint at exactly the right time.

ASTM F2620 Compliant

In developing this breakthrough technology, McElroy partnered with the University of Tulsa to test hundreds of fusion joints, analyzing thousands of data points and modeling computational fluid dynamics to understand core pipe temperatures for compliance with ASTM F2620-19 Note 10 and help assure safe handling.

HAVE A QUESTION OR PROJECT TO DISCUSS? GET IN TOUCH!

[gravityform id="11" title="true"]